Choosing of LVT tiles, same as any other floor coating, starts with determination of requirements applicable to them, primarily this is the wear resistance class, fire certification and floor space. Generally, in public spaces tiles with a protective layer of minimum 0.55 mm and KM2 certificate are laid by gluing method, whereas for domestic use any type of coating can be chosen if it is suitable for the consumer's budget. The basic parameters to pay attention to are as follows:

- type of tile laying (glue-type tiles are more difficult to lay and are more demanding of substrate smoothness as compared to lock-type tiles)

- lock type: some advanced types of locks, such as DreamClick, allow for a designer type of laying

- protective layer: the thicker it is the more wear resistant is the coating. For domestic use generally a layer of 0.3 mm is sufficient

Together with the experts of the B. I. G. company, we will analyze in detail the features of different PVC tiles and find out its pros and cons.

What are the options for PVC tiles?

SP SPC (Stone Polymer/Plastic Composite) — tiles made of stone-polymer (plastic) composite;

WPC (Wood Polymer/Plastic Composite) — tiles made of wood-polymer (plastic) composite;

L LVT (Luxury Vinyl Tiles) - premium vinyl tiles

The main composition of all the same: marble powder (limestone), polyvinyl chloride (PVC) and a small amount of chemical additives.

What is quartz vinyl tile?

Sometimes on the shelves of construction stores you can find the so-called quartz vinyl tiles. In fact, this is another "popular" name for a standard LVT tile, and not a new type of coating.

SPC-tile

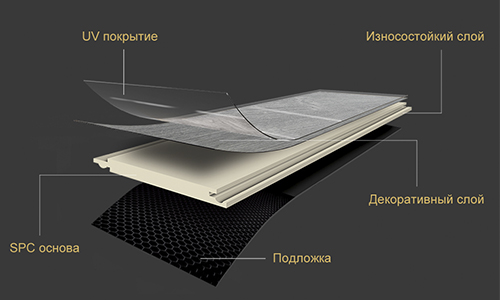

Tiles made using SPC technology are characterized by increased strength and are equipped with locking joints, similar to those used in laminate.Technical specifications

In the composition of SPC tiles, the proportion of PVC is reduced and the content of the mineral component-marble powder — is increased to increase the strength. As a rule, there are no additional plasticizing agents in this type of tile.

As a result, the finished coating of SPC tiles is solid and resistant to fluctuations in indoor temperature. Such tiles are not recommended to bend or fold in half — cracks may occur. However, this advice is also relevant for other types of PVC tiles.

Styling features

Modules of the SPC type are fastened together with a lock around the perimeter of the tile and are laid in a floating way, without rigid fixation to the base of the floor. The locking connection significantly simplifies the laying of the coating and significantly increases the speed of installation.

Despite the increased hardness of the material, it is important to properly prepare the base, otherwise there is a risk of damaging the locks. Here, as for other types of floor coverings, the base should be dry, strong, solid, without bumps and debris. Read more about preparing the foundation here.

Operation features

SPC-tile is a dense floor covering that does not absorb and does not spring under your feet. But it is this rigidity that allows the tile to retain its original geometry longer and better resist intensive use.

Expert recommendations

For those who are primarily interested in the strength of the coating and ease of installation, we suggest paying attention to the PURELOC 40 and CARMELITA collections.

Design 1682

WPC tile

The second type of PVC tile — WPC, is an alternative version of SPC.

Technical specifications

The main component of WPC is wood flour, which partially replaces the traditional limestone. The appearance of this type of PVC tile is an attempt to create both a strong and comfortable/soft coating.

The addition of a wood component really made the WPC modules as comfortable as possible among the entire line of PVC tiles. With a strength comparable to LVT, WPC tiles are characterized by a greater thickness and, as a result, improved shock-absorbing properties.

The downside of the increase in size was the increased problem of sensitivity to indoor microclimate — WPC tiles expand and contract with changes in temperature and humidity. For this reason, according to industry experts, this type of coating will disappear from the market in the future.

Styling features

The WPC modules are provided with a lock connection and are laid in a floating way, without rigid fixation to the base, similar to laminate or SPC tiles. The requirements for the base are general – dry, strong, smooth, clean.

LVT-tile

LVT is the most flexible floor covering of all PVC tiles. How to choose it correctly, we have discussed in detail in our article " How to choose LVT»

Technical specifications

The composition of LVT tiles contains more polyvinyl chloride, which is responsible for flexibility, and less mineral component — limestone, which is responsible for rigidity. To make the tile even more elastic, plasticizers are added to its composition.

Styling features

LVT-tiles can be laid either with glue or with a lock, depending on the design. At the same time, laying on glue is preferable, since the coating is rigidly fixed to the base of the floor.

Important! Working with glue requires certain skills, so it is better to invite specialists to perform high-quality installation.

Bonding minimizes the risk of tile deformation due to temperature changes and prevents the appearance of gaps in the joints. Therefore, it is the adhesive method of laying (even for coatings with a lock) that is recommended in public and industrial premises.

The requirements for the base are general – dry, strong, smooth, clean.

Operation features

From the point of view of everyday use, the LVT tile coating is comfortable — due to the initial flexibility, the material significantly dampens underfoot, giving a better load distribution on the spine, compared to rigid ceramics or granite. In general, LVT is resistant to external influences, but you should be careful with heavy pieces of furniture: it can leave traces, so we recommend using special pads on the legs.

For more information about the installation and maintenance of LVT, see the section "Installation and maintenance".

Expert recommendations

For residential areas, B. I. G. experts recommend LTV tiles from the SPIRIT HOME 30 Glue down collection. If this type of coating is planned to be laid on commercial objects, then the SPIRIT PRO 55 Gluedown collection will be the best choice.

Design Cement Light Grey

Let's sum up the results

1. PVC tile is a modular system of floor coverings and is a full-fledged alternative to such familiar materials as ceramic tiles, laminate, linoleum.

2. Manufacturers of PVC tiles produce three main types — LVT, SPC and WPC-each of which represents a certain balance of key characteristics (flexibility, strength and installation features). The range of B. I. G. collections mainly includes LVT and SPC floor coverings, as they better meet the key requirements of today's consumers.

3. To choose the right PVC tile, it is recommended to study the pros and cons of each type, take into account the characteristics of the room and the necessary performance properties of the final floor covering.